Industrial enamel paint is a high-performance paint widely used in industrial environments that require high-strength protection. Compared with other types of paint, industrial enamel paint not only has strong anti-corrosion and wear resistance, but also can provide long-term protection and beautiful appearance for metals and other materials in extreme environments. However, despite the excellent characteristics of enamel paint, it is not necessary or appropriate to use it in all situations.

So, when should industrial enamel paint be used? This news will explore the applicable occasions, characteristics and application examples of industrial enamel paint in different industrial fields in depth, to help readers better understand when and where to use industrial enamel paint.

What is industrial enamel paint?

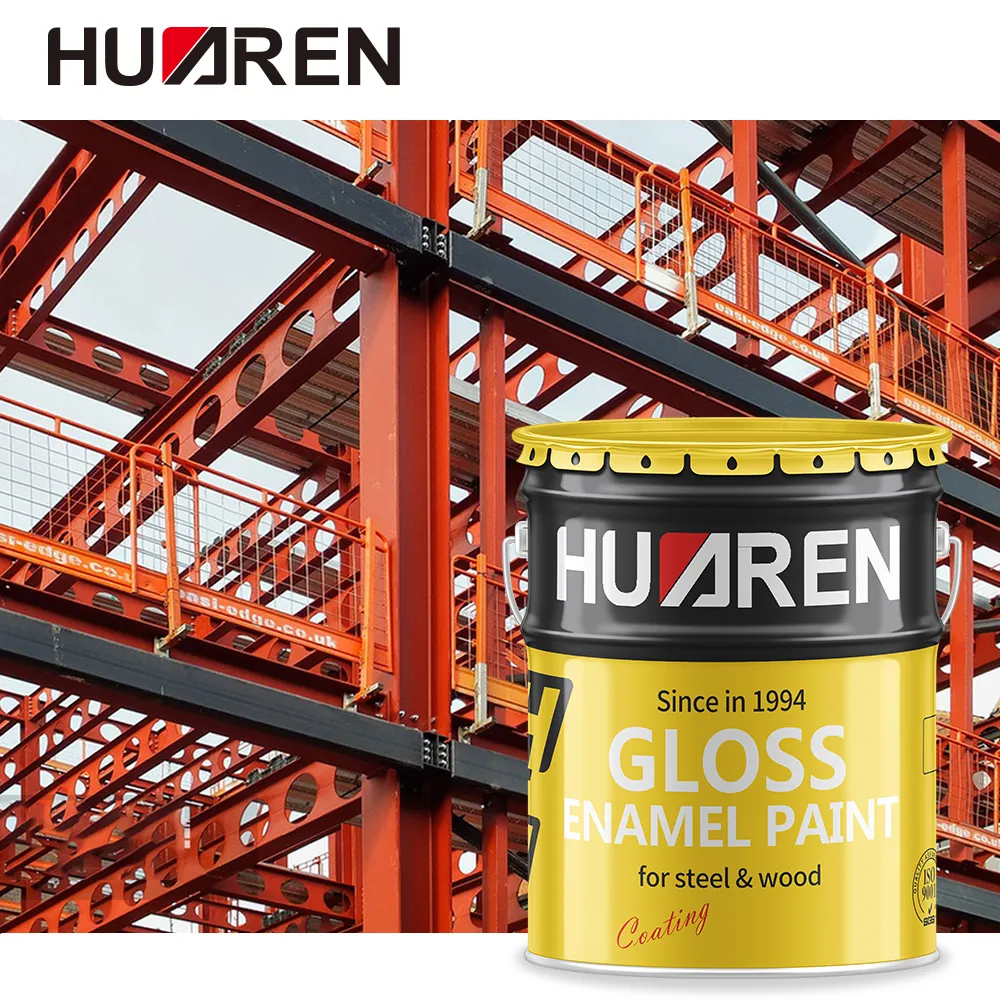

Industrial enamel paint, usually composed of resin, pigment, drier and solvent, is a coating used for metal, wood and other materials. The biggest difference between enamel paint and ordinary paint is its high hardness, glossiness and durability. After curing, the coating forms a smooth and hard surface similar to ceramic, which can resist wear, impact, chemical erosion and extreme weather conditions.

Industrial enamel paint is often used in outdoor and harsh industrial environments due to its durability, such as surface coating of ships, bridges, storage tanks, steel structures and machinery and equipment. Compared with ordinary paints or coatings, enamel paint can provide more lasting protection when exposed to extreme conditions such as high temperature, ultraviolet rays, acid and alkali.

When should industrial enamel paint be used?

Typical occasions for using industrial enamel paint:

1. Metal surface corrosion protection

2. High temperature or extreme climate environment

3. Chemical corrosion resistance requirements

4. Occasions requiring high gloss and aesthetics

5. High wear or heavy load environment

Metal surface corrosion protection

Metal surfaces, especially metal structures exposed outdoors, such as steel beams, pipelines and bridges, are extremely susceptible to oxygen and moisture in the air, resulting in oxidation and rust. Rust not only affects the appearance, but also weakens the strength of metal structures and increases maintenance costs. In this case, the use of industrial enamel paint is an ideal solution.

Industrial enamel paint can form a hard protective film on the metal surface, effectively preventing air, moisture and other corrosive substances from coming into direct contact with the metal. This coating can significantly extend the service life of the metal and reduce the frequency of regular maintenance.

High temperature or extreme climate environment

In high temperature environments or extreme climate conditions, ordinary paints often cannot withstand long-term temperature changes and sun and rain, and are prone to cracking, fading or peeling. Industrial enamel paint is an ideal coating choice for these environments due to its excellent high temperature resistance.

For example, in high temperature industrial environments such as chemical plants and refineries, equipment and pipelines are often exposed to extremely high temperatures. Industrial enamel paint can maintain its physical and chemical properties stable and will not fail due to temperature changes. Even in the scorching sun or severe cold, the enamel paint coating can maintain a bright and intact surface for a long time.

Chemical resistance needs

In some industrial facilities, such as chemical plants, pharmaceutical plants or wastewater treatment plants, equipment and pipelines are often exposed to acids, alkalis, salts and other corrosive chemicals. Under these conditions, traditional coatings are difficult to provide long-term protection and are easily corroded, causing equipment aging and damage. Industrial enamel paint has a very strong chemical resistance and can effectively resist the erosion of these harmful substances.

In chemical facilities, enamel paint can be used as a protective layer, applied to the surface of tanks, pipes and containers to prevent chemical damage to equipment. This coating not only improves the safety of the facility, but also extends its service life and reduces the frequency of equipment replacement and maintenance.

Occasions requiring high gloss and aesthetics

In addition to its strong protective properties, another advantage of industrial enamel paint is its smooth surface and high gloss. In some industrial projects, in addition to durability, aesthetics is also very important. For example, the surface coating of automobiles, household appliances and high-end mechanical equipment usually requires not only a strong and durable coating, but also a high-gloss appearance.

After drying, enamel paint forms a smooth and shiny surface that can add beauty to the product. This coating is particularly suitable for the exterior treatment of automobiles and equipment because it can maintain its bright color and gloss for a long time while resisting daily wear and environmental damage.

High wear or heavy load environment

Industrial equipment and machinery are often subjected to frequent friction and impact under high-intensity operation, such as construction machinery, mining equipment and ship surfaces. The surface protection of these equipment requires the coating to remain intact during long-term wear, and the high hardness of industrial enamel paint makes it particularly suitable for such high-wear environments.

For example, on mining and construction sites, the surface of equipment is often impacted and scratched by sand, gravel and soil, and ordinary paint is prone to rapid wear. Industrial enamel paint can provide long-term wear protection in such harsh environments, effectively extending the service life of equipment.

What are the advantages of industrial enamel paint?

Excellent durability

The hard coating formed by industrial enamel paint after curing can provide extremely high durability. Whether it is exposed to sunlight and rain outdoors or faced with high temperature and chemical erosion in industrial environments, enamel paint can maintain its original performance and is not easy to fade, peel or crack. This makes it an ideal choice for applications that require long-term protection and low maintenance.

Strong chemical resistance

Due to the special anti-corrosion ingredients in the formula of industrial enamel paint, it can effectively resist the attack of corrosive substances such as acids and alkalis. This makes it widely used in corrosive environments such as chemical plants and pharmaceutical plants. Compared with ordinary paints, the chemical resistance of enamel paint greatly improves the safety of equipment.

Smooth surface and easy to clean

The coating surface formed by enamel paint after curing is very smooth, which not only makes it beautiful, but also easy to clean and maintain. Dust, dirt and pollutants are difficult to adhere to the enamel paint coating, which is particularly important in places with high cleanliness requirements such as food processing plants and hospitals.

Resistance to high temperature and climatic conditions

The high temperature resistance of industrial enamel paint enables it to be used in extreme climatic conditions without aging, cracking and other problems. Even in extreme temperature changes, it can maintain stable physical and chemical properties, suitable for various outdoor and industrial facilities.

Long-lasting gloss and color

After drying, enamel paint can form a shiny and bright surface and can maintain bright colors for a long time. This makes it the first choice in some industrial occasions that require beautiful appearance, such as automobile manufacturing, home appliance surface treatment, etc.

How to choose the right industrial enamel paint?

First, choose the right enamel paint according to the specific working environment. If the equipment or structure is exposed to high temperature, corrosive chemicals or humid environment, the corresponding high temperature and chemical corrosion resistant enamel paint should be selected. Secondly, enamel paint is usually applied to metal surfaces, but it can also be used for materials such as wood and plastic. The adhesion and construction requirements of different substrates are different, so the right substrate coating should be selected. In addition, the corresponding coating process should be selected according to the drying and curing method of the enamel paint. Industrial enamel paint usually requires high temperature baking to achieve the best effect, but there are also some low temperature curing products available.